The color fastness to rubbing is the most basic evaluation index for the color fastness of textile products.

The main problems of SME products in terms of color fastness to rubbing are:

1. The color fastness to wet rubbing of medium and dark cotton, linen and their blended products is mostly below 2-3, which is lower than the requirements of general standards.

2. The color fastness to dry rubbing of some dark, thin and fuzzing products containing wool is much lower than that of wet rubbing.

3. The color fastness to dry rubbing of some rough or raised fabrics, including paint dyeing and printing products, does not meet the minimum requirements of the standard.

1.1 Color fastness to wet rubbing

Direct dyes are used for the dyeing of cellulose fibers, and the color fastness to wet rubbing and the color fastness to washing are not ideal.

Causes:

The affinity of direct dyes to cellulose is mainly based on dipole attraction and dispersion. The combination of this adsorption is not strong, especially in the wet state, the hydrogen bond may be stronger.

Insoluble azo dyes dye cellulose fiber products, and their color fastness to rubbing is not ideal.

Causes:

Factors Affecting the Color Fastness of Reactive Dyes to Wet Rubbing

1. The structure and characteristics of reactive dyes themselves

2. The properties of cellulose fabrics

3. Pre-treatment effect, cloth surface damage and smooth surface

4. Dyeing process and the effect of soaping after dyeing

5. The effect of fixing treatment after dyeing the fabric

6. The effect of dyeing fabric finishing and the effect of cellulose fiber degradation

Fiber fabrics dyed with reactive dyes will cause color transfer in the wet rubbing fastness test.

major factor:

The water-soluble dye fades the original color and stains the rubbing cloth during rubbing. Part of the dyed fiber breaks when rubbed, forming tiny colored fiber particles, causing staining.

The color fastness to wet rubbing of fabrics dyed with reactive dyes is closely related to the depth of dyeing. Among them, the supersaturation of the dye is the most important factor.

How to effectively improve the color fastness to wet rubbing of fabrics?

Proper pre-treatment of cellulose fiber before dyeing, such as mercerizing, singeing, cellulase finishing, desizing and scouring, bleaching, washing, and drying, can improve the surface finish and hair effect of the fabric, and reduce friction resistance. , Reduce floating color.

1.2 Color fastness to dry rubbing:

Some specific fabrics (lightweight fabrics, rough surface or sanded fabrics, raised fabrics) do not meet the standard requirements.

Lightweight fabrics fail to meet the requirements for dry friction resistance.

Causes:

Because the fabric structure is relatively loose, during dry friction, the sample will partly slip with the movement of the friction head under the action of pressure and friction, which increases the friction resistance and improves the friction efficiency.

The color fastness to dry rubbing of velvet or napped fabric is decreased.

Causes:

The fluff on the surface of the fabric and the surface of the friction cloth are at a certain angle, not parallel, so that the friction resistance of the friction head increases when it reciprocates.

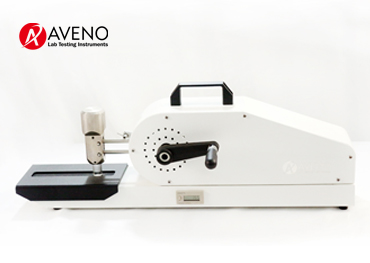

AVENO Machine Recommend:

AC04 AATCC Electronic Crockmeter

AC04-2 AATCC Electronic Crockmeter

AC04-3 AATCC Electronic Crockmeter

AC05 AATCC Crockmeter(Rubbing Fastness Tester)

AC05B AATCC Crockmeter

+8615280858852

+8615280858852

Feb 16, 2026

Feb 16, 2026

online service

online service +8615280858852

+8615280858852

+8615280858852

+8615280858852