Textile Test Equipment

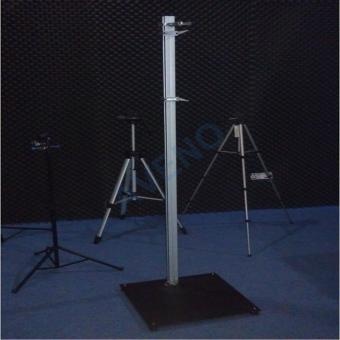

After over 20 years of development, AVENO Tester has become a professional manufacturer and supplier of Textile Testing Equipment in China, offering custom services: Minimum Order Quantity: 1 unit is sufficient inventory. Customization Services Available: Custom workstations, fixtures, and designs are available. Experienced R&D Team: With over 10 years of experience, our team continuously optimizes our products. Quality Control: Products undergo at least five quality inspections over multiple days before shipment.

+8615280858852

+8615280858852

Mar 02, 2026

Mar 02, 2026

online service

online service +8615280858852

+8615280858852

+8615280858852

+8615280858852