In order to the accuracy of experimental data and the normal operation of experimental instruments, the daily maintenance of laboratory instruments is of great significance. The laboratory should formulate a reasonable maintenance plan according to the use conditions of different instruments. A reasonable maintenance plan can improve the accuracy and functionality of laboratory testing equipment, reduce the failure rate, improve the use rate and prolong the service life of equipment.

Laboratory equipment managers should be familiar with the working principle of each instrument and understand the functionality and working mode of each component of each instrument and equipment, so as to formulate maintenance contents for the functional components of the instrument. Generally, the common maintenance contents are as follows:

1. Check the appearance and operation of functional components

2. Cleaning

3. Add lubricating oil, antirust oil, etc

4. Replace consumables / accessories

General principles for selecting maintenance intervals and times

Equipment maintenance is aimed at all the instruments in the laboratory:

1. Determine the frequency of the cycle according to the working principle of the instrument and the frequency of use;

2. Appropriately relax or shorten the maintenance cycle according to the harsh environment of the equipment;

3. Cooperate with the equipment period inspection. Generally speaking, equipment maintenance should be arranged before each equipment period inspection to ensure that the equipment is in the best condition during the period inspection.

The routine maintenance of general equipment can be controlled at about twice a year. Under special circumstances or special equipment, flexible maintenance shall be carried out according to the specific actual situation:

1. The equipment with periodic replacement of consumables shall flexibly grasp the cycle according to the specific replacement cycle;

2. For the equipment working in the unavoidable harsh environment, the maintenance times shall be appropriately increased according to the actual situation without affecting the test;

3. It is recommended to arrange a maintenance before the equipment is checked during the period;

4. For equipment with high frequency of use, the number of maintenance shall be appropriately increased.

Routine maintenance of common laboratory testing instruments

1. ICI Pilling and Snagging Tester

Regularly wipe the surface of the cork liner with a trace amount of methanol, clean the roller box before and after the test, check whether the cork liner falls off and whether there are sharp objects on the surface, and regularly clean the exposed parts of the rotating shaft and bearings to prevent fiber residues and yarn residues. On the bearing, the rotation of the roller box is stuck and the rotation speed is abnormal. After confirming that there is no residue on the rotating shaft and the bearing, add lubricating oil.

More about AVENO AG05 ICI Pilling and Snagging Tester

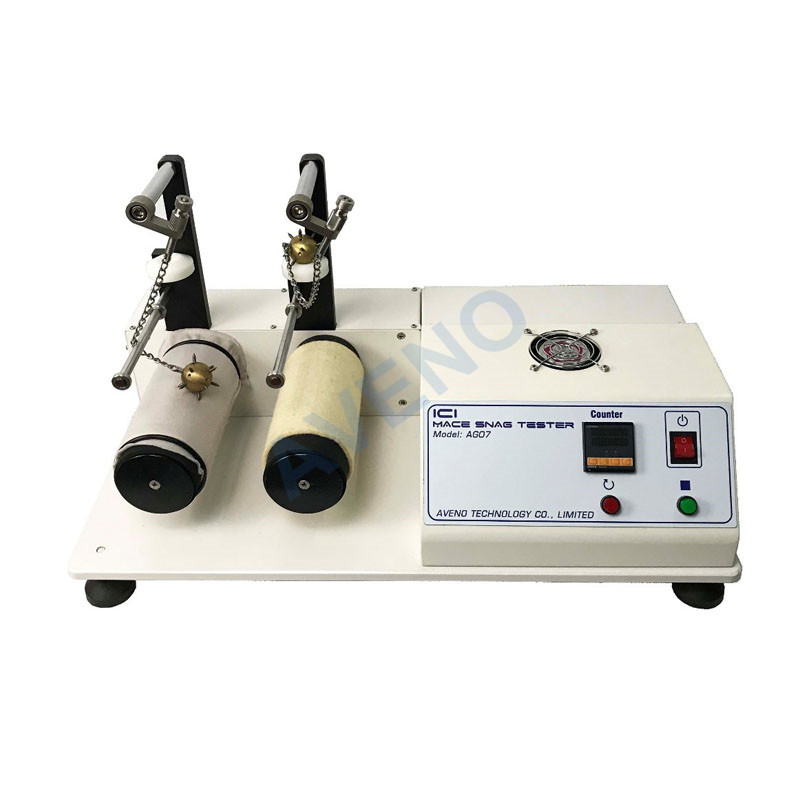

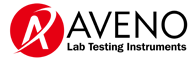

2. ICI Mace Snag Tester

Before and after the test, check whether the tungsten needle on the weight is missing and the tip is broken. Regularly clean the rotating bearing to prevent fiber residue and yarn from remaining on the bearing, causing the rotation to be stuck and the rotation speed to be abnormal. Clean the drive chain and add lubricating oil.

More about AVENO AG07 ICI Mace Snag Tester

3. Automatic Wascator Shrinkage Tester

The drain valve needs to be cleaned regularly to ensure smooth drainage. Failure to clean for a long time may slow down the drainage speed or interrupt the automatic operation program. After each test, check whether there are residues in the drum, such as fiber residues, zipper heads, buttons, etc.

More about AVENO AC13 Automatic Wascator Shrinkage Tester

4. Light Fastness Tester

It is necessary to regularly calibrate the lamp irradiance and the blackboard temperature according to the equipment instruction manual, especially when the detection standard is changed, it is necessary to ensure the accuracy of the blackboard temperature, replace the relevant components in time, and replace the filter (cleaning) in time. The reflector under the sample holder needs to be wiped clean.

More about AVENO AC01 Light Fastness Tester (air-cool) & AC02 Light Fastness Tester (water-cool)

5. Single Yarn Strength Tester

Regularly clean the lifting bearing of the powerful machine and add lubricating oil. Clean the fiber residue on the surface of the instrument with an air gun before work every day. If the air compressor is equipped, drain the air compressor regularly to prevent the water of the air compressor from entering the instrument through the air pipe and damaging the circuit board of the instrument.

More about AVENO AY05 Single Yarn Strength Tester

6. All equipments requiring water operation

The water tank shall be changed and cleaned regularly. Pure water is preferred to avoid dirt in the water tank and blocking the pipeline and pump.

In addition to the above examples, the maintenance of other equipment should also be carried out regularly, and professional manufacturers should be contacted for guidance if necessary.

Contact Us Now!

Sales Dept Tel: +86 15280858852

Email: sales@avenotester.com

Skype: sales@avenotester.com

Web: www.avenotester.com

+8615280858852

+8615280858852

Jan 02, 2026

Jan 02, 2026

online service

online service +8615280858852

+8615280858852

+8615280858852

+8615280858852