1.Installed abrasive paper (before installation, please put gloves, the fingers were not galled by sand)

-

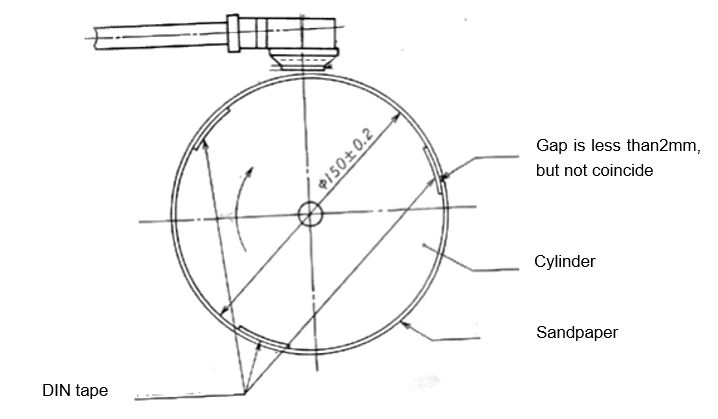

Get abrasive paper that length is 473 +-1mm and width is 400 mm at least. But those two items do not exceed roller, the average thickness is about 1.0 0.2 mm.

-

Get three bars double-face tape that is equal to roller, the thickness is 0.2mm at most, the width is 50mm, add them on roller well-distributed. At some time, every double-face tape will be parallel with axial lead of roller; one bar was stick on the two sides layup of abrasive paper.

-

When fixed abrasive paper, the direction should be same both marking arrow direction of abrasive paper back and test operation, it should be stick on roller tightly, the front and back two sides of abrasive paper should be aligned, at some time, the two short side should is parallel with roller axis.

-

When abrasive paper two sides were stick, the gap is not exceed 2mm, but it won not be coincided.

-

Abrasive papers will be rough after changing; it must be polished by round metal block. (No load condition)

【Note】

1) Roller must be no dust and clean. When changing old abrasive paper, the double-face tape on roller should be swept clearly. The abrasive paper is clean after polishing.

2) When sticking abrasive paper, please use fine abrasive paper to polish the two sides’ joint of abrasive paste face.

-

The testing method of using standard rubber to modify the abrasive paper consumptions, and insure it whether keeps in 180 mg ~ 220 mg:

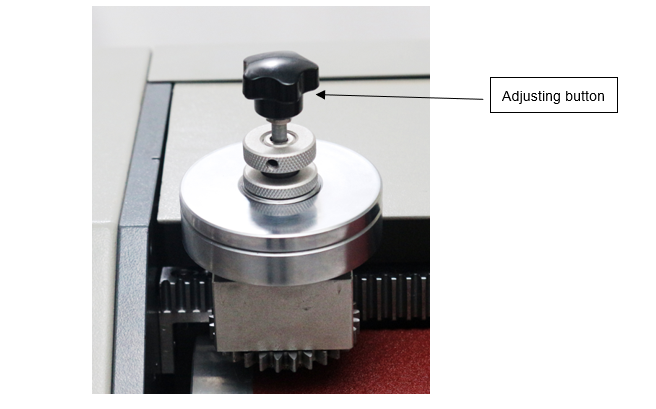

2.Pick up the whole bracket upward to original site, the following is the picture:

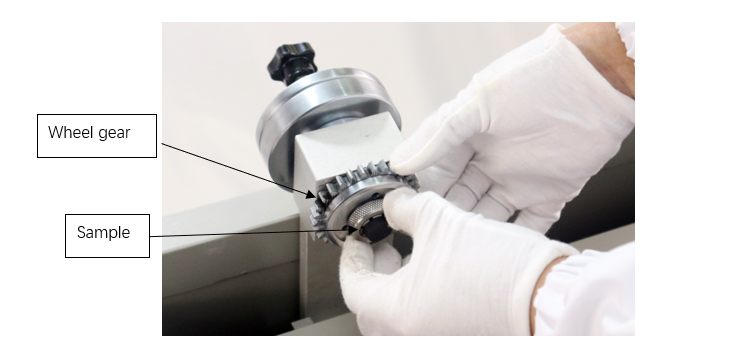

3.Grip standard rubber

-

Loosing screw nut at the anti-clockwise direction, the collet will became large, and put standard rubber(the standard rubber can be used, but the thickness or the total thickness of standard rubber stick on the rubber materials shall be more than 6mm) into collet inner, pressing sample and locking screw nut at the clockwise direction.

-

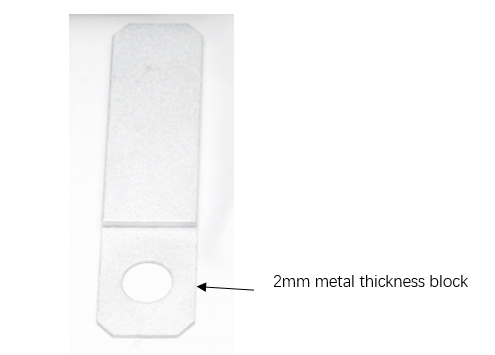

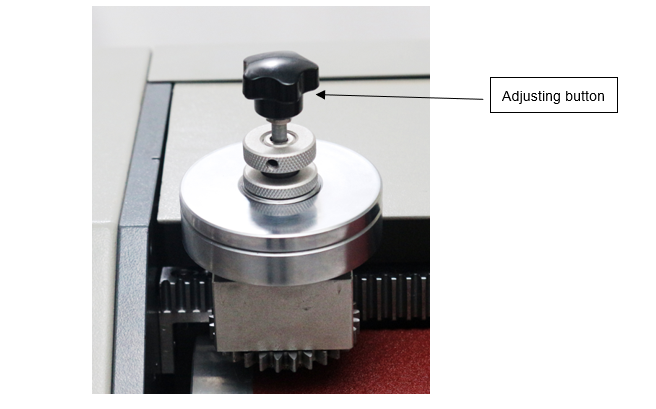

Put the metal that thickness is 2 mm on well- DIN Abrasion Tester standard rubber, adjusting bolt at the anti-clockwise or clockwise direction, standard rubber is parallel with metal thickness chunk (let the standard rubber show collet about 2 0.2 mm)

4.Moving whole bracket to original site, and put it on guide rod pulley just like picture seven.

5.Put weight of the 2.5N and 5.0N on load seat, just like picture 8.

6.Start Test:

-

Put the pipe of the cleaner onto the interface, Let moving pipe of cleaner stay in the original place during testing and there is 1mm between sandpaper and pipe.

-

Contact the right switch power supply, start button ”POWER” (as picture2-4),push button ”START”(as picture2-2). Pre-grinding first, make sure the sandpaper can match the Standard rubberpre-grinding. After half of the pre-grinding, push button ”STOP”(as picture 2-3),stop means in the middle of the guide pulley on the red horizon Standard, mark on the standard plastic clip head.

-

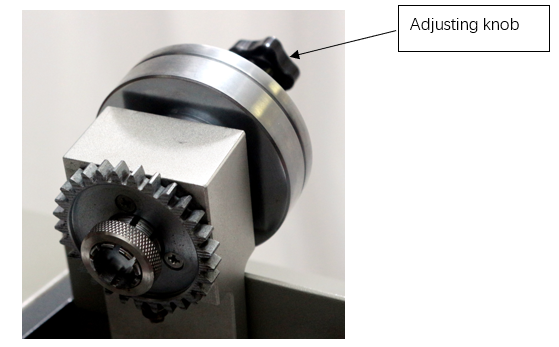

Push forward adjusting knob hardly (as picture5) or unscrew the nut in a counterclockwise direction (as picture6), from standard rubber rod clamp head to remove surface residual colloidal particles, and weighed in the balance (W1), accurate to 1 mg.

-

Then make it back to the starting point until the whole bracket backward bracket can move freely, holding the weighed standard rubber in 2.5.3 again, note: the standard glue mark on front side.

-

Push button “START” again (as picture2-2). Begin to grind to 40 m trip (84 RPM), the machine will automatically filed after the whole trip.

-

Take off the standard from clamp head, get rid of surface residual colloidal particles, weighed in the balance (W2) again. Accurate to 1 mg.

-

Test at least three standards, take the average.

-

Using the following formula to calculate the standard quality of rubber abrasion: Q = W1 - W2

7.Test Sample:

-

To test sample after we known abrasion weight of standard rubber.

-

Reduce the weight of testing samples (such as the operation of standard rubber). Test three samples, take the average.

-

Calculate the abrasion weight of samples, △m=the weight of the sample after preliminary grinding (half the itinerary) - the weight of the sample after testing (the whole itinerary)

-

Use electronic balance to test sample’s proportion (S).

-

After finished testing, switch off the power of Shoe DIN Type Abrasion Tester.

8.Evaluation of result:

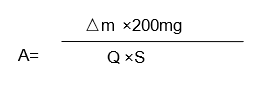

Substitute the number into the following formula, calculate value of abrasion A(mm3).

△ m: the weight of sample abrasion, mg;

Q: the weight of standard rubber abrasion, mg;

S: the proportion of sample, (mg/ mm3)

-

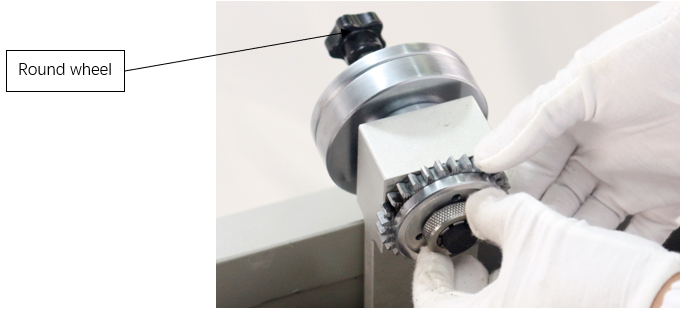

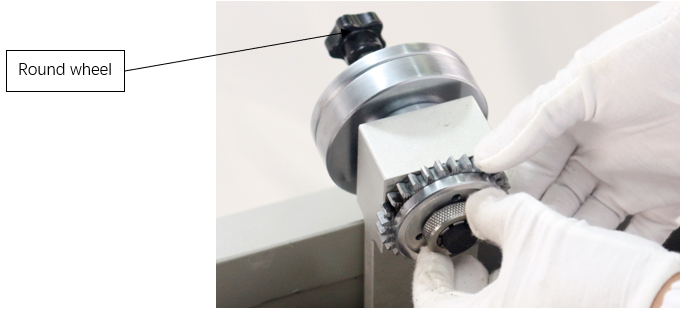

When you want to make the sample non-rotation, do as the picture 7, take down the gear with six angles, change the round wheel of company attachment, and fix it on the clamp head, at the same time, lock screws on the holder.

AVENO Machine Recommend:

AF02 DIN Abrasion Tester

Contact Us Now!

Sales Dept Tel: +86

15280858852

Email: sales@avenotester.com

Skype: sales@avenotester.com

Web: www.avenotester.com

+8615280858852

+8615280858852 +8615280858852

+8615280858852

online service

online service +8615280858852

+8615280858852 sales@avenotester.com

sales@avenotester.com +8615280858852

+8615280858852