+8615280858852

+8615280858852

+8615280858852

+8615280858852

There are many kinds of textile fabrics. As a raw material of textiles, yarn is processed into products of a certain fineness with various textile fibers, which are used for weaving, rope making, thread making, knitting and embroidery, etc. Filament etc.

Fabric type analysis involves examining the fabric to determine its composition, construction, and other characteristics. This can include identifying the type of fiber used, the yarn count, weave structure, and other details. Dyeing and finishing defect analysis involves examining fabrics for any flaws or defects that may have occurred during dyeing or finishing processes. Finally, it can also involve testing for shrinkage or fading of the fabric.

Textile fabrics are divided into woven fabrics, knitted fabrics and non-woven fabrics.

Woven fabric is a fabric made of two or more groups of mutually perpendicular yarns interwoven at a 90-degree angle as warp and weft. The longitudinal yarns are called warp yarns, and the horizontal yarns are called weft yarns. The advantages of woven fabrics are good hand feeling, good moisture absorption performance, smooth hand feeling, and not easy to deform. The disadvantage is that it has poor elasticity and is easy to wrinkle.

Knitted fabrics include warp-knitted fabrics and weft-knitted fabrics. Warp-knitted fabrics are warp-knitted (vertical) loops that cannot be spun off artificially. Weft-knitted fabrics are weft-wise (horizontal) loops. Woven cloth that can be loosened manually.

Due to the characteristics of the weaving method, knitted fabrics are prone to more quality problems in the production process. Unlike the quality problems of woven fabrics, most of the weaving defects of knitted fabrics are irreparable, and only a small part can be saved.

Routine testing of woven fabrics

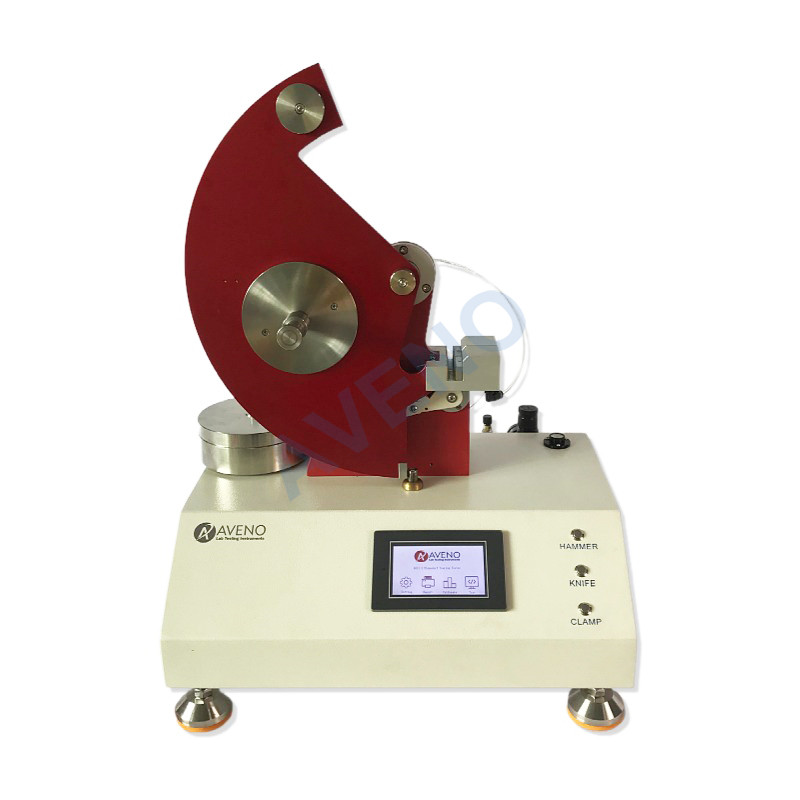

1. Tear performance

When the fabric has gaps (cracks, cuts), use an electronic tearing tester to apply tension on both sides of the gap to show the destruction process of the yarn being pulled off one by one, which is called fabric tearing.

AVENO Tear Tester please click: https://www.avenotester.com/Tearing-Tester_c0_ss

2. Flaw performance

Using a Dynamic Seams Fatigue Tester, test the degree of seam release and the maximum distance that the yarn slips to create a void when the sample is stretched to the specified load.

Using a Dynamic Seams Fatigue Tester, test the degree of seam release and the maximum distance that the yarn slips to create a void when the sample is stretched to the specified load.

Routine testing of knitted fabrics

1. Bursting performance:

Use the spherical mandrel of the Ball Burst Strength Tester to press the sample in a direction perpendicular to the plane of the sample until the sample is pressed in the direction of the plane until the sample is broken. The maximum force value measured during the process is the top Break the strength.

2. Pilling performance: GB/T 4802.1-2008 Circular trajectory pilling: According to the specified method and test parameters, use the Automatic Fabric Stiffness Tester, use nylon brush and fabric abrasive or only fabric abrasive to make the sample fluff and pill, use standard sample According to the grade of the evaluation sample.

3. Color fastness test

Fastness to rubbing: Use a Crockmeter to rub the textile sample with a dry rubbing cloth and a wet rubbing cloth respectively, and evaluate the staining degree of the rubbing cloth.

4. Light fastness: use a Light Fastness Tester to expose the textile sample and a group of blue wool standard samples under artificial light sources under specified conditions, and then compare the color change of the sample with the blue wool standard sample to evaluate the color fastness.

Any demand can be referred to us!

Sales Dept Tel: +86 15280858852

Email: sales@avenotester.com

Skype: sales@avenotester.com

Web: www.avenotester.com

online service

online service +8615280858852

+8615280858852 sales@avenotester.com

sales@avenotester.com +8615280858852

+8615280858852