Jun 01, 2025

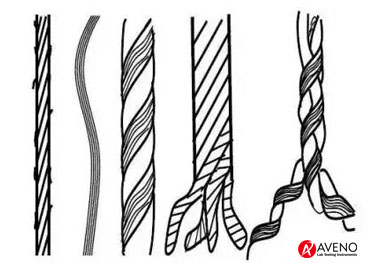

Hey, dear friends! Today is Children's Day, which is full of joy and innocence! We usually go all out at work and fight for our dreams, but don't forget that we all have a childlike innocence deep in our hearts. Children's Day is an opportunity to awaken that pure beauty. I hope everyone can be like a child, keep curious about the world, always have a smile in their eyes, and face every bit of life and work with simple happiness. AVENO also wish all the little babies in the families of my colleagues a happy Children's Day. May they grow up healthily, be surrounded by happiness every day, and always keep their innocent appearance. Let us bring this innocence and create more beauty for the company and life together! AVENO Founded in 1998, AVENO is mainly engaged in textile test equipment, footwear test equipment, toy test equipment and other laboratory testing instruments, which are favored and recognized by customers at home and abroad. AVENO TECHNOLOGY CO., LIMITED Sales Dept Tel: +86 15280858852 Email: sales@avenotester.com Skype: sales@avenotester.com Web: www.avenotester.com

+8615280858852

+8615280858852

Jan 02, 2026

Jan 02, 2026

online service

online service +8615280858852

+8615280858852

+8615280858852

+8615280858852