22 Jul, 2021

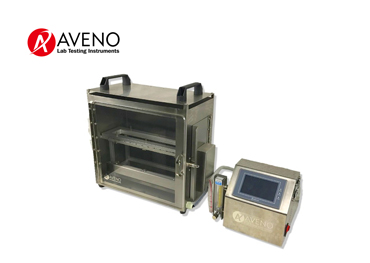

1 Overview of Water Cool Light Fastness Tester AC02 Light Fastness Tester (water-cool) is a testing machine developed by our company according to the requirements of national standards and AATCC standards. The machine adopts the latest sensor technology and microcomputer control technology, and has the advantages of high measurement and control accuracy, high intelligence, stable and reliable performance; simple and clear interface, easy operation, etc. Light Fashtness Testing Equipment complies with AATCC TM16-2003 and GB/T8427-1998, GB/T8430-1998, GB/T14576-93, GB/T15102-2006, GB/T15104-2006, ISO 105 B02 and other related requirements. It is suitable for the test of light fastness, weather fastness, light fastness and perspiration fastness to various colored textiles; it can also be used for the light fastness of paints, pigments, coatings, rubber, plastics, wood floors, paper and other materials Fastness test and light aging test. 2 Main feature of Light Fastness Test Chamber 1.2.1. Adopt 4500W long arc xenon lamp to truly simulate the sunlight spectrum; 1.2.2. High-transmittance filter combination, using 95% transmittance filter and filter tube, to achieve the same irradiance light requirements with low power consumption, making the instrument more energy-saving and environmentally friendly; 1.2.3. Standard 420nm band, irradiance digital setting, real-time monitoring, closed-loop automatic adjustment, providing the most stable irradiance test light source for different standards (340nm, 420nm, 300-400nm and 300-800nm bands are optional) ; 1.2.4. Light energy conversion technology is used to provide energy for radiometer detection and wireless transmission, without additional power supply; 1.2.5. Blackboard thermometer (BPT), standard blackboard thermometer (BST), radiometer and sample are tested at the same station (equidistant), which truly reflects the tested condition of the sample, and the measured data is synchronously transmitted by radio frequency technology; 1.2.6. Industrial temperature control (refrigeration) system, the water tank is heated to generate water vapor to control the humidification system, and quickly adjust the temperature and humidity in the test chamber to ensure that the test temperature and humidity are accurate and stable; 1.2.7. Multiple operating modes (drenching in rain, alternating light and dark), which can simulate the real climate state; 1.2.8. All sample holders can be timed separately, and different samples can be tested on the same machine, which is convenient for testing and monitoring and reduces operating costs. Running time and separate timing can be powered off to prevent accidental power off; 1.2.9, 10.1-inch large color touch screen, multiple test monitoring modes (animation, numbers, charts), easy to operate, intuitive and clear; 1.2.10. The quality guarantee that one test can run continuously for 1000 hours; 1.2.11. Industrial-grade single-chip microcomputer control, strong anti-interference abi...

read more

+8615280858852

+8615280858852

Feb 16, 2026

Feb 16, 2026

online service

online service +8615280858852

+8615280858852

+8615280858852

+8615280858852