+8615280858852

+8615280858852

+8615280858852

+8615280858852

Clothes pilling I believe that many people have encountered the experience of clothes pilling after wearing them for a period of time.

Why do clothes pill?

In the process of wearing clothes again, they are constantly rubbed, so that the fiber ends on the surface of the fabric are pulled, belted, hooked, pulled out, and the phenomenon of hairiness formed on the surface of the fabric is called fluffing. As the hairiness is gradually pulled out, generally more than 5mm, and then subjected to friction, the fiber ends will be hooked and entangled with each other to form an irregular spherical shape, which is called pilling.

Generally speaking, wool fibers and chemical fibers are easy to pilling, especially woolen fabrics or woolen like woolen fabrics and cashmere fabrics. From the point of view of yarn and structure, twill and satin fabrics with small twist, more hairiness, loose structure and long floating thread are easy to pilling.

How does the inspector test pilling?

In order to ensure the safety and comfort of the garment, a piece of fabric will undergo various tests before it is made into a garment, including the pilling test.

The test methods for clothing pilling mainly include: " Circular trajectory method", " Martindale method", "Pilling box method" and "Random Tumble Pilling Test method".

Although they all test the pilling degree of fabrics, the above different methods are applicable to different clothing fabrics, and the working principles of the instruments are also different. No matter which method is used, the pilling performance of the test is expressed in the form of grades, generally divided into grades 1 to 5, and the larger the grade, the less likely the clothes are to pill. The general standard stipulates that the index ≥ 3 is a qualified product.

The principle of GB/T 4802.1—2008 "Circular trajectory method" is that the sample is rubbed with nylon brush and fabric abrasive or only with fabric abrasive for a specified number of times under specified pressure, so that the surface of the sample is fluffed and pilled.

This method has a faster test speed and can simulate the friction and pilling of the fabric after being hooked. It is suitable for wearing woven fabrics and knitted fabrics such as sweaters and T-shirts.

Circular Locus Pilling Tester(Circular trajectory method) AG34

Its principle is that the circular sample is rubbed against the fabric of the same material under a given pressure with the trajectory of the Lissajous figure, and after the specified number of revolutions is reached, the pilling level of the sample is evaluated. It is suitable for bed category testing.

Martindale Abrasion and Pilling Tester AG04

Its principle is mainly: the sample is installed on the polyurethane tube, and it is turned arbitrarily in a wooden box lined with cork with a constant rotation speed. After the specified number of turns, the fuzzing and (or) pilling performance is evaluated visually. It is suitable for the detection of sweater textiles.

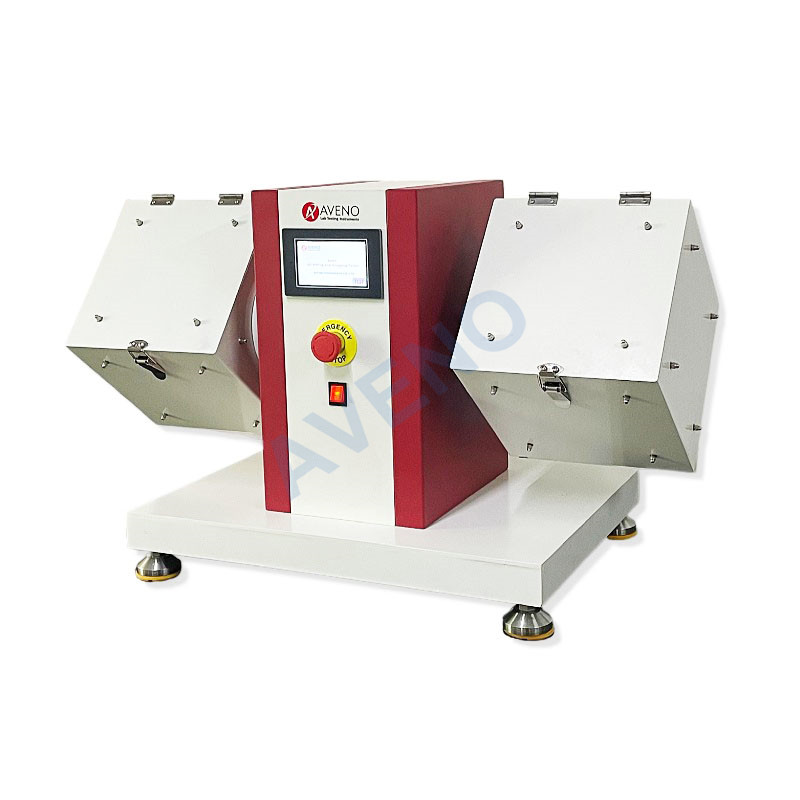

ICI Pilling and Snagging Tester AG05

4. Random Tumble Pilling Test method

Its principle is to use a random tumbling pilling box to make the fabric roll and rub freely in a cylindrical test chamber covered with cork pads and filled with a small amount of short gray cotton.

Random Tumble Pilling Tester AG15

Any demand can be referred to us!

Sales Dept Tel: +86 15280858852

Email: sales@avenotester.com

Skype: sales@avenotester.com

Web: www.avenotester.com

online service

online service +8615280858852

+8615280858852 sales@avenotester.com

sales@avenotester.com +8615280858852

+8615280858852